hydro jetting machine checklist

Get SAFETY WORK PERMIT prior to hydrotest. All high pressure water jetting equipment and actions will comply with AustralianNew.

364 Pre Job Check List High Pressure Hydro Jetting Rev 000 Pdf Valve Nozzle

Never direct the spray jet at the machine itself or any electrical equipment.

. A continuous flow of water is sent through a homes plumbing system to dislodge any materials that have become clogged inside the affected pipes. Experts push the high-pressure water through your pipes using a special hydro jetting machine. What is Hydro Jet Drain Cleaning.

Heres a rundown on hydro-jetting equipment that you can expect a professional to use for drain cleaning in Raleigh NC. ABOUT Established in 1996 in Ahmedabad India. John Holland Group Created Date.

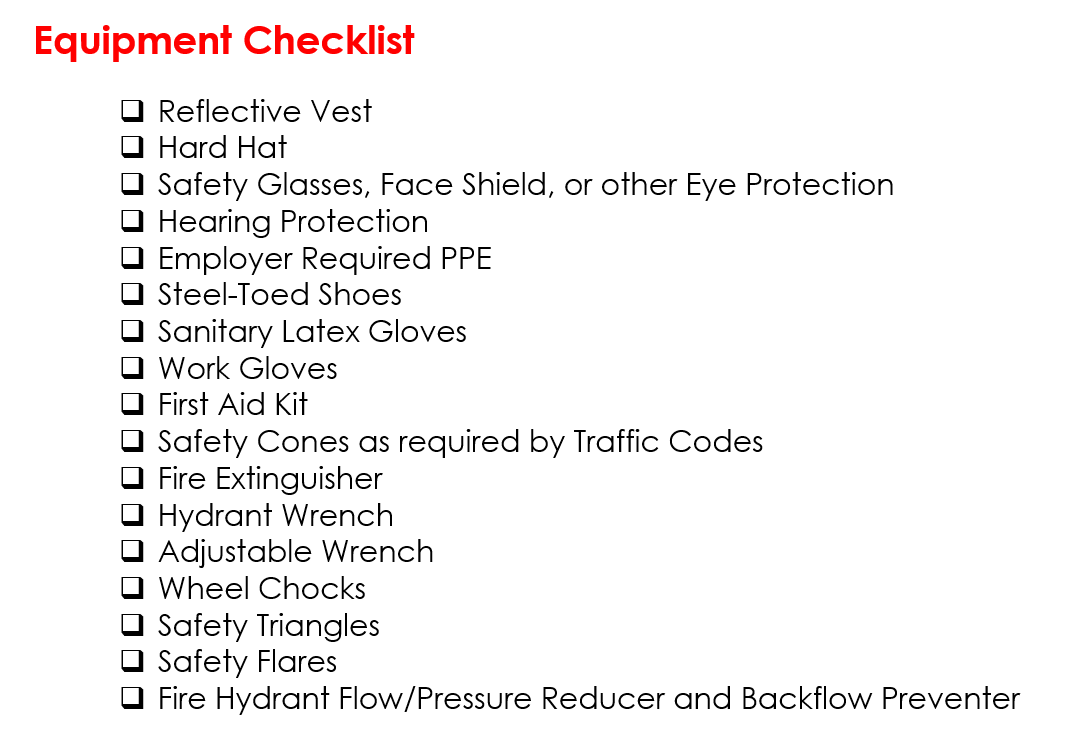

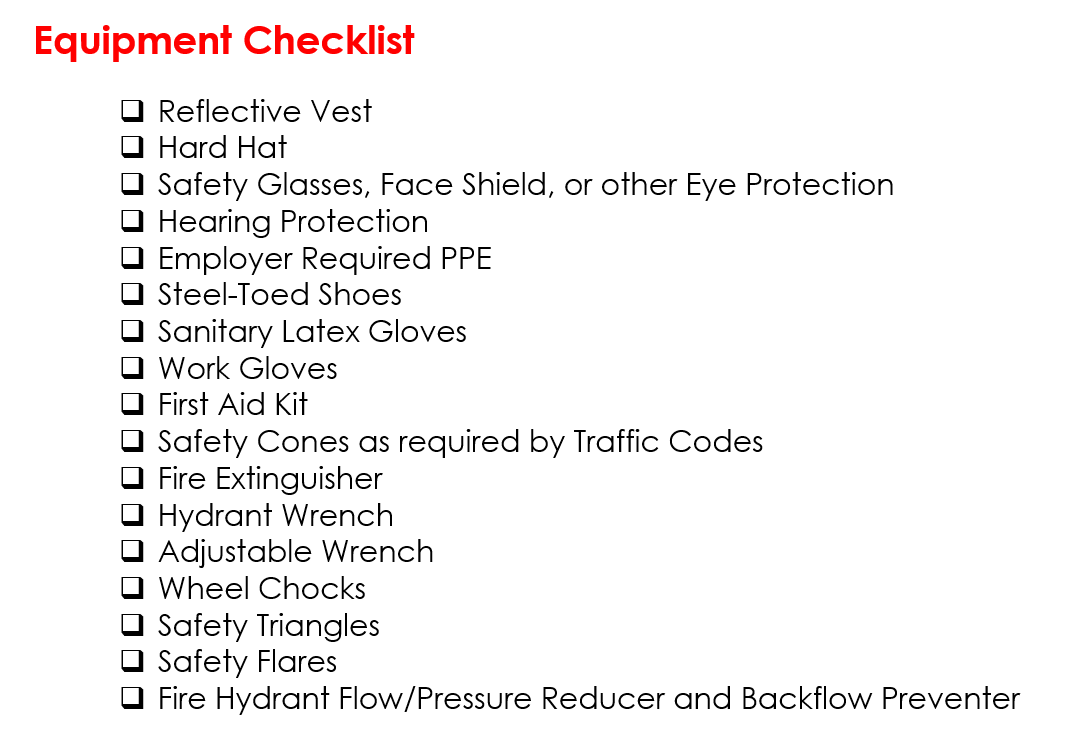

Safety practices must always be adhered to when overhead electrical lines and electrical equipment are present. The impact of a high pressure nozzle leaky hose or being hit by contaminated waste can cause potentially life threatening injuries. Tube cleaning - loose little hard scale and short length tubes.

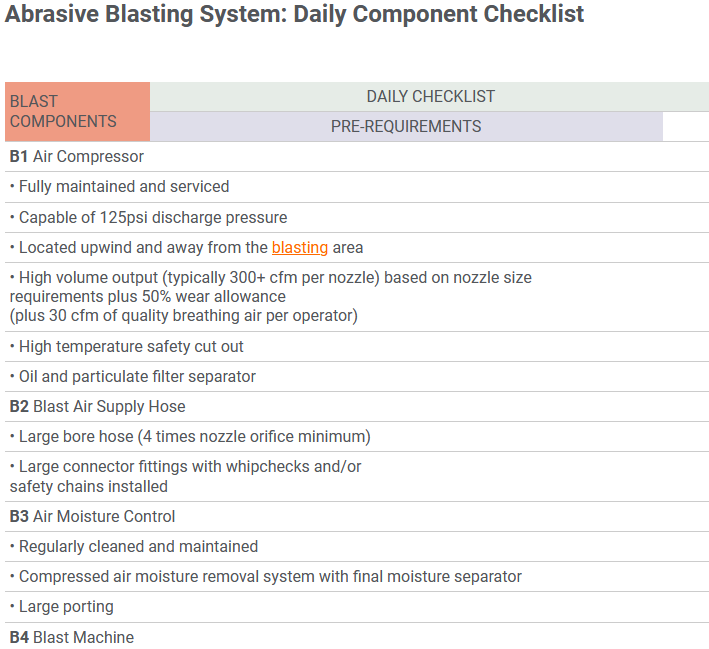

All electrical equipment required to support the - hydroblasting operations must be equipped to prevent electrocution eg grounded GFCI 32 Never use abrasive jetting in atmospheres above 10 LEL. It involves the use of high-pressure water jets which can remove debris clogs and buildup from the plumbing system. Face shields Clear shield nine inches deep by fifteen and one-half inches wide by 060 thick ANSI Z871-1979 or equivalent.

Use CALIBRATED pressure gauge for the test. More than 1500 loyal customers and 5000 successful pumps installations worldwide. Give us a call 247365 at 800 481-3707 and find out how we can save you both time and money.

Face shields Clear shield nine inches deep by fifteen and one-half inches wide by 060 thick ANSI Z871-1979 or equivalent. The following identifies at a minimum the personal protective equipment that will be issued to employees performing high-pressure water cleaning outside of the required hardhat and safety glasses with side shields. Class a high pressure water jetting systems 800 5600 BAR LITRES PER MINUTE PLANT PRE-ACCEPTANCE CHECKLIST.

COMMUNICATE the test planning prior to execution. See the WJTA-IMCAs Recommended Practices for the use of high-pressure water jetting equipment andor the Water Jetting Associations WJA Code of Practice for additional safety information. Hydro jetting encompasses a process that relies on using pressurized water to clear pipes.

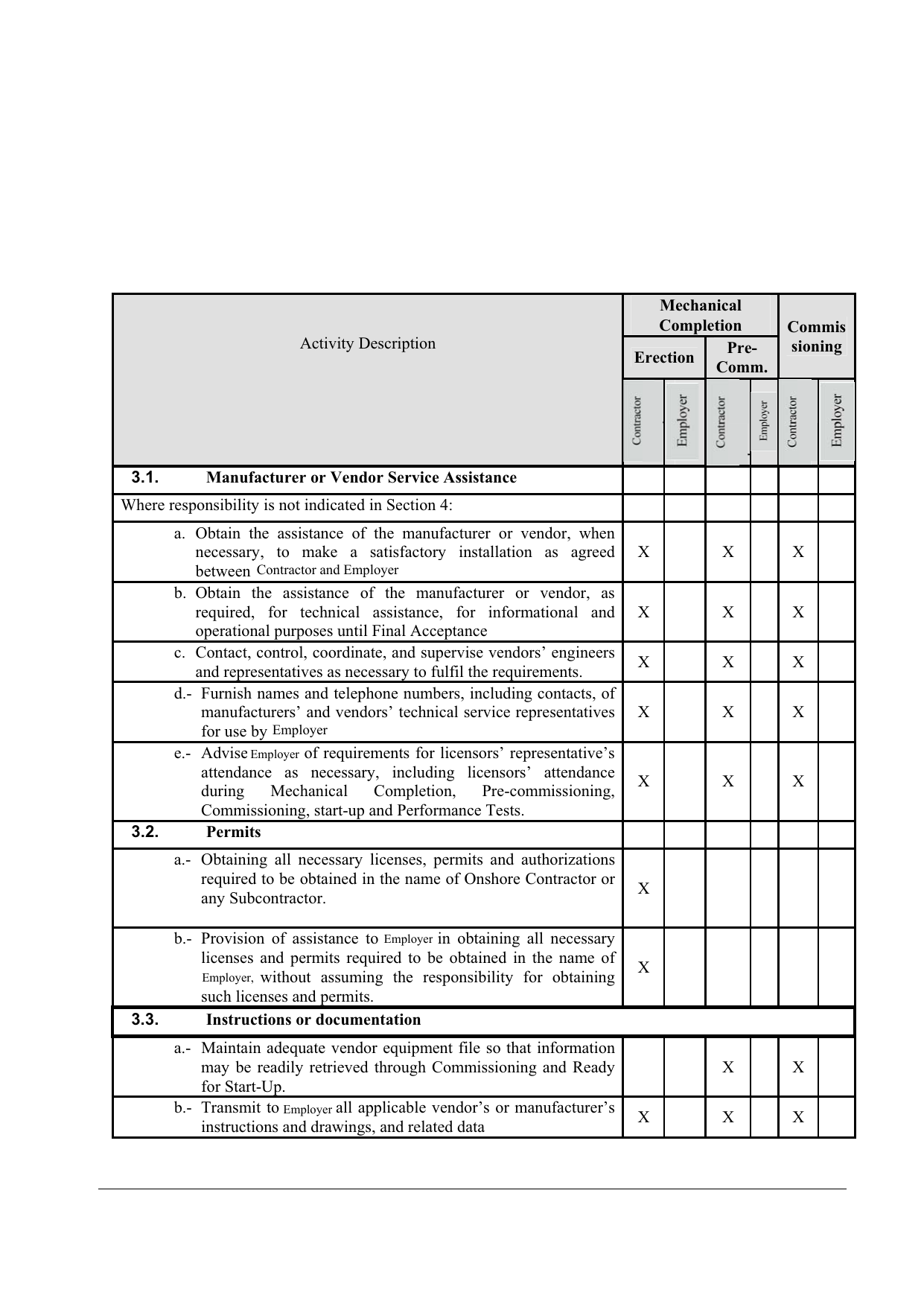

It apply to mechanics supervisors inspectors custodians and subcontractors responsible for pressure tests. This process rids the interior of the pipe from built-up debris that has triggered a clog or slower flow. Safe movement distances must also be monitored when the boom is in use.

Award Winning Radio Control. Hydro Jetting is a non-invasive plumbing solution that clears pipes by removing blockages effectively. Zealand Standard ASNZS 42331 High Pressure Water Hydro Jetting Systems.

If you have questions about your pharmacy benefit call 877-861-0376. PRESSUREJET manufactures High Pressure Hydro Jetting Machine for the pressures ranging from140 bar 2000 PSI to 1400 bar 20000 PSI This pressure range meet the tube cleaning requirements of most industrial applications. The power behind the hydro-jetter is the motor or engine which can run from electricity or sometimes gasoline.

Hydro-jetting is a process that involves high-pressure water in order to unclog pipes. The most popular jetting model the 4000PSI at 18GPM uses US Jettings brand of ½ high pressure hose rated for 16k burst pressure. Serious injury when the water jet comes into contact with skin or eyes.

Complete a job specific risk assessment. 31 Water jetting plant and equipment 10 32 Medical alert card 12 4. Guidelines for Safe Operation and Maintenance.

31 All electrical equipment that may be impacted by hydroblasting including overspray must be covered deenergized or otherwise protected. In cases of grease buildup hot water is often used to. Were Sewer Pros a licensed and insured sewer repair and replacement contractor performing hydro jetting for customers in both Los Angeles and Orange County.

CLASS A HIGH PRESSURE WATER JETTING SYSTEMS PLANT PRE-ACCEPTANCE CHECKLIST Last modified by. Hydro-jetting is a very safe process that doesnt use abrasive materials or technologies that may cause harm. The purpose of these checklist is to ensure that pressure tests are conducted safely and effectively.

STOP the work if unsafe or potential hazardous condition found during the test. By Sewer Pros. It places water at the very high pressure necessary for the hydro-jetter to work.

This hose is specifically designed for longevity and durability while maintaining a high level of safety. When not in use always switch off the engine depressurise all hoses and disconnect from water supply. Always follow the Jetting Safety Procedures when operating any drain line sewer jetting equipment.

Hydro jetting systems normally run at around 2000 to 4000 PSI pounds per square inch which is strong enough to cut through tree roots up. It cover pressure testing of new and existing pressure systems or components at a test pressure more than 0 psig. Hydro jetting is a method professional plumbing contractors use to clean clogged or slow sewage lines.

In the past rodding was the only solution through which plumbers powered a hole through the accumulation. Weve specialized in. It must be able to cover 15 to 2 times pressure test.

After use release the pressure in the high pressure hose by operating the hose reel ball valve or gun trigger if using gunlance. Additional 38 ¼ and 316 hoses can also be added to jet smaller pipes down to 1. The following trailer pre-operation inspection checklist is a great tool for making sure trailers are properly prepared for hauling and road travel.

When voltage is unknown it is required that all personnel and equipment on-site keep back a minimum of 7 meters from overhead lines. Install mechanical stops stingers and back out preventers as appropriate when doing any tube pipe or vessel cleaning. Hydro jetting machine checklist.

When jetting is performed in confined spaces other OSHA rules for confined space entry and personal protective equipment must be followed. It utilizes high-pressure water to remove blockages and build-up. Equipment that does not comply with ASNZS 4233 will not be used.

Install Friday May 13 2022 Edit. An ISO 90012015 certified company Manufacturing various applications pumps like Water Jet Cleaning Hydro Test Hydro Jetting Hydro Blasting Sewer Jetting Fire Fighting many more applications. EQUIPMENT CARE AND MAINTENANCE 13 41 Pump unit 13 42 Filters and strainers 13 43 Hose assemblies 13 44 Nozzles 14 45 High pressure jetting guns 16 46 Foot control devices 18 47 Hose connection and layout 18 48 Electrical equipment 19.

Pre Operation Checklist Safetyculture

High Pressure Water Jetting Equipment Hydrojet Equipment Pressurejet

Essential Equipment For Essential Operations Vac Con

Exxi A R Epc Schedule 10 Mechanical Completion Checklist Execution Version 3

364 Pre Job Check List High Pressure Hydro Jetting Rev 000 Pdf Valve Nozzle

Jsa Hydro Jetting Pdf Personal Protective Equipment Safety

Pdf Management Of Industrial High Pressure Fluid Injection Injuries Ihpfii The Water Jetting Association Wja Experience With Water Driven Injuries

Hydro Jetting Services Clear Drain Blockages Maffei Services Plumber Ma Maffei Plumbers

364 Pre Job Check List High Pressure Hydro Jetting Rev 000 Pdf Valve Nozzle

High Pressure Water Jetting Pdf Free Download

Doc Identification Of Risk And Providing Guidance For Operation And Maintenance Gowtham Sundhar Academia Edu

Abrasive Blasting System Daily Component Checklist Blast Booths Spray Paint Booths Abrasives Media And Equipment